|

|

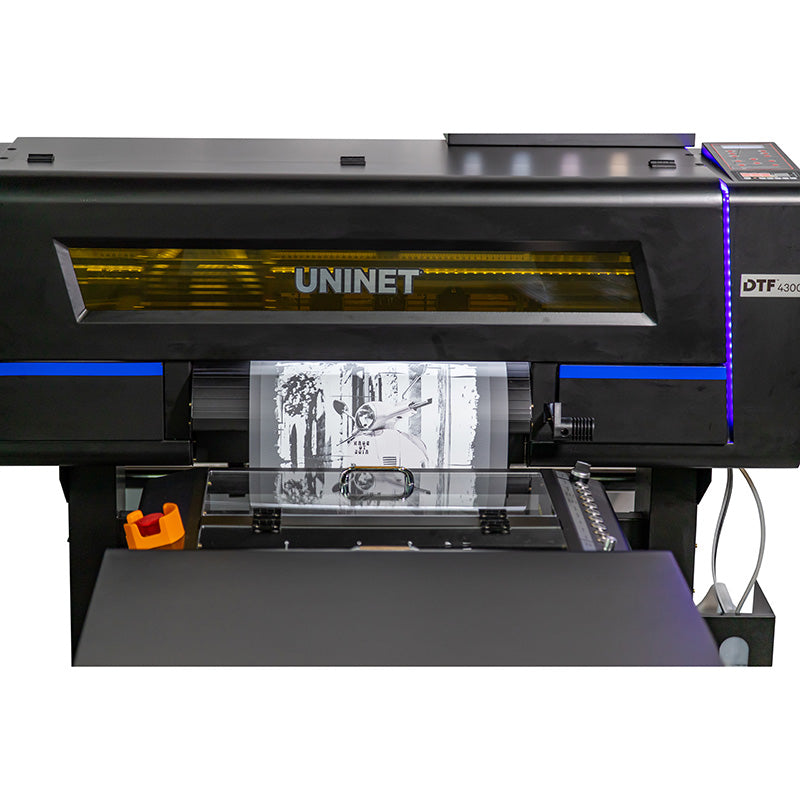

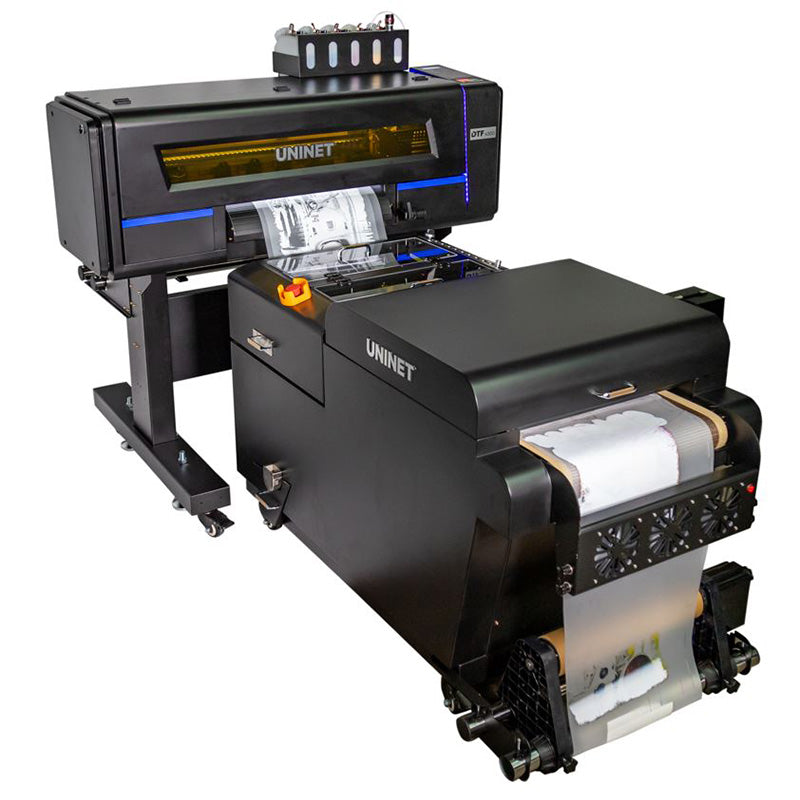

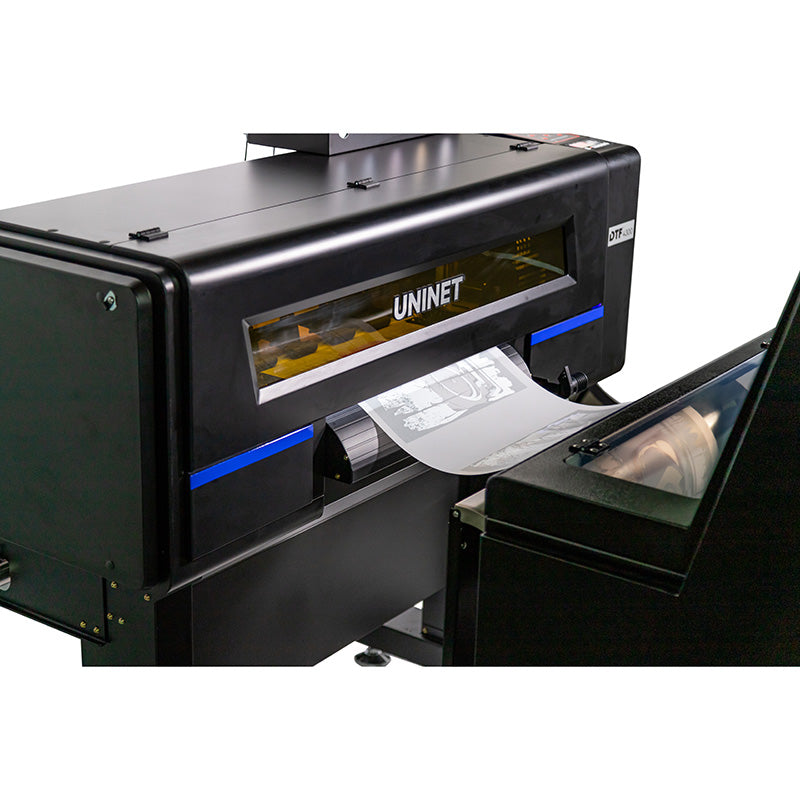

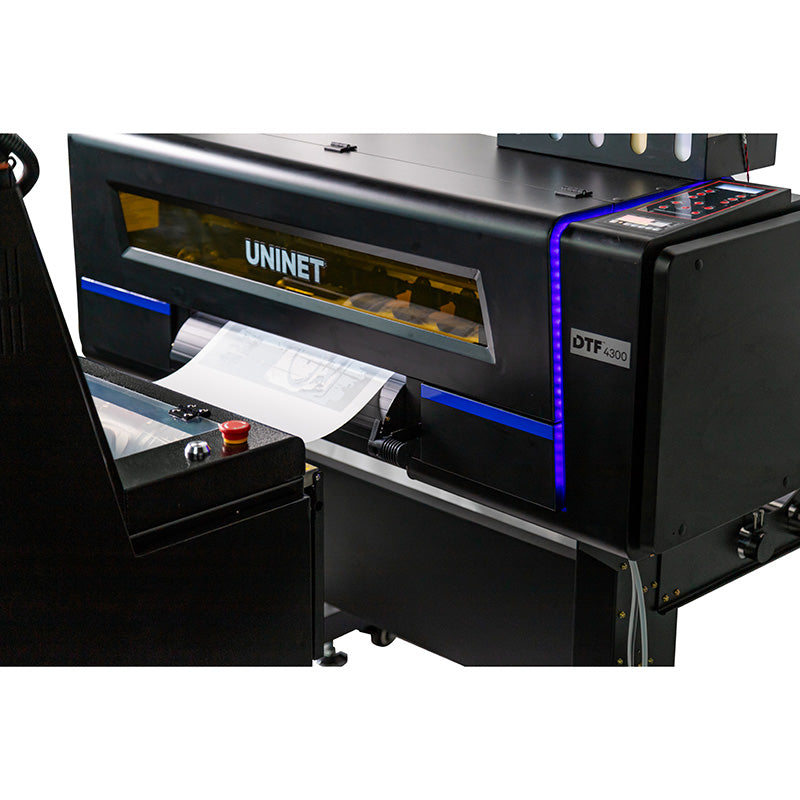

UNINET DTF 4300 Digital Transfer Printer

Say “high” to the UNINET® DTF™ 4300 Transfer Printer.

|

|

| FEATURES: |

|

| INCLUDES: |

|

| WHAT'S NOT INCLUDED BUT YOU MAY NEED: |

|

|

APPLICATION INSTRUCTIONS (Using UNINET Triple Coated, Cold Peel Film and UNINET inks) |

|

When using the heat station (manual process): Recommended temperature for DTF powder curing: Application to substrate: COTTONS and BLENDS: • Press at 300 - 325°F for 10 – 12 seconds • Post press for 5 – 10 seconds *Hoodies may require 325°F and up POLYESTERS / TRI-BLENDS: • 265 – 275°F for 8 – 10 seconds • Post press for 5 – 10 seconds * Thinner material may require lighter pressure; otherwise the transfer can leave a ‘window’ on the garment and/or scorching may occur. *Polyester settings can vary, but best to use lower temperature and pressure generally 50 / 50: • 275°F for 12 seconds • Post press for 5 – 10 seconds COTTON: • 310 - 325°F for 15 seconds • Post press for 10 seconds FINISHING: • Matte finish – Kraft paper, T Seal or parchment cover sheet. • Shiny/gloss finish - Teflon cover sheet *Specialty silicone pads with texture can be used to prevent gloss look, gives print a nice textured feel. ADDITIONAL SUGGESTIONS: • Thicker fabrics require more heat, generally. • Hats (poly) may require 245 - 250°F for 5 - 8 seconds • Umbrellas, EZ-ups, stadium chairs will require testing and trial and error. *Be careful of dye / ink migration with polyester textiles - perform a 24hr test (fine tuning) to see if the ink migrates (clothing dye reacts with the DTF ink) GARMENT TYPES: • DTF works with almost all fabrics and garment types: • Combed Cotton, Ring Spun Cotton, Organic Cotton, Polyesters, Blended Fabrics, Poly-Cottons, Tri-Blends, Polyester-Spandex, Leather, Vinyl, Denim, Canvas and much more. |

| TECHNICAL SPECIFICATIONS |

|

• PRINT SPEED: up to 44 - 50 square ft / hr (~20 A2 pages/hr) |

|

|

|

|

|

|

|

|

|

|

|

|

|