-

Automatic Maintenance-Free DTF Printing with XTF™ Technology

UNINET’S exclusive XTF™ Technology eliminates the hassle of routine DTF maintenance. The printer features a first-of-its-kind patented Automatic Wet Cap & Wiper Cleaning System. It keeps nozzles clog-free and printheads performing at their best — without manual cleaning or messy solutions. An innovation, the printer has two onboard cleaning cartridges that handle wet capping automatically. Just tap the display, and the system handles maintenance on its own, reducing downtime, preventing banding, and extending printhead life. With XTF™, the “X” marks out the maintenance — giving you consistent, worry-free production every time.

-

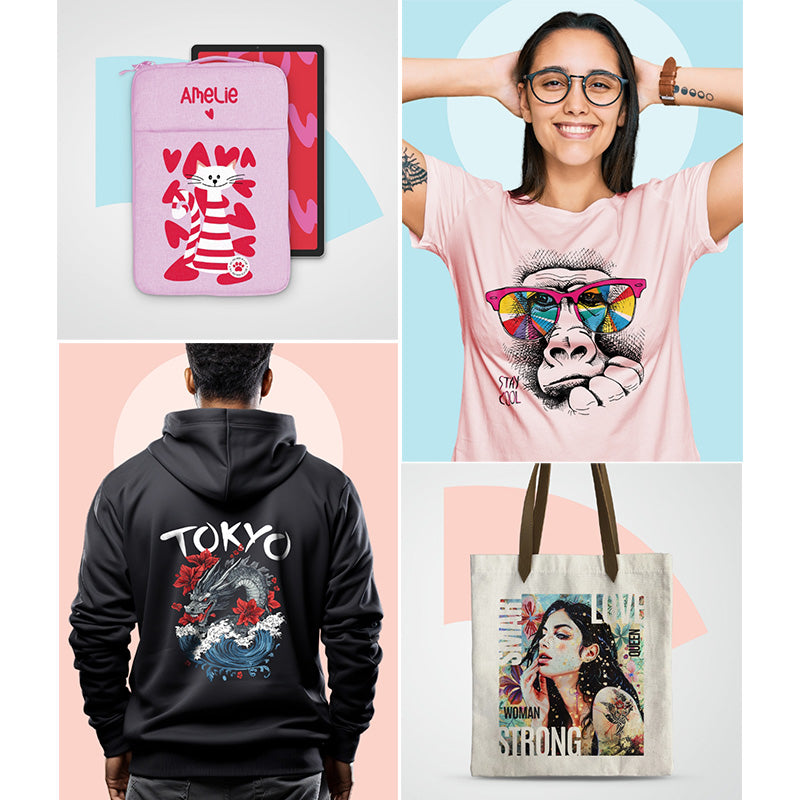

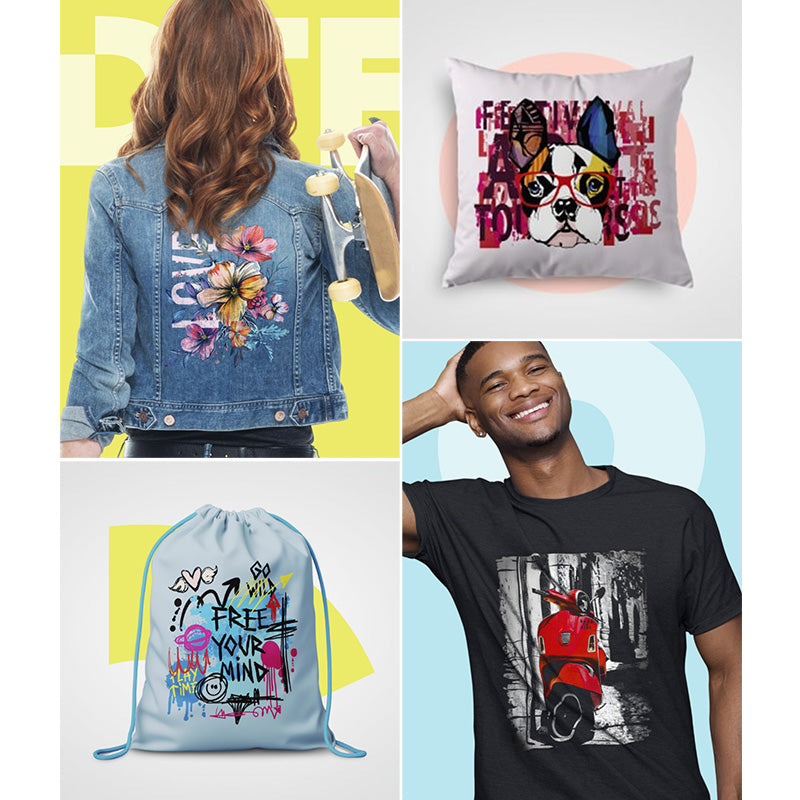

17” Wide Format Continuous Printing Capability

Produce superior-quality transfer prints for customized apparel, garments, accessories, and more. Supports medium to large volume jobs without compromising detail, color vibrancy, or consistency.

-

Built for Speed & Volume

Engineered for enhanced reliability and high-speed performance. Our industrial-grade printheads outperform standard film-type piezo heads found in other machines, delivering superior output without sacrificing quality.

-

Clean & Consistent Output

Its turbo-charged Seal Ink System prevents ink contamination and evaporation, delivering mess-free performance and stable print quality, so you can focus on growing your business instead of cleaning up.

-

Independently Controlled 4-Zone Heater System

Achieve flawless results with our precision-engineered four-zone heater, designed for optimal film transfer printing. Each zone operates independently to ensure rapid, even drying, keeping color and white ink layers sharp and distinct, regardless of ink volume.

-

Compact Design, Big Power

Save space without sacrificing productivity, it fits through standard 32” doorways —perfect for small studios or high-demand production floors.

|